|

SRV - Service Management

The after-sales warranty and services provided to the customer are the most important factors today that cast many products, especially durable goods, in a more favorable light against their competitors. In today's competitive environment, the most expedient short-cut to gain customer trust in the product and in the manufacturer rests in both the product and the manufacturer having a strong service network. If you cannot provide warranty for the products you manufacture, you accept up front the fact that the product will not stand much of a chance to exist in its respective market.

How easy is it then to provide warranty for your products, and establish and manage a service network for the entire region where you perform your marketing activities?

- Do you have problems identifying your customers and tracking their purchases?

- Would you like to set up a system to monitor the performance of your authorized service centers and assure that they live up to your quality standards?

- Does your service management system fall short in helping you plan for your spare parts needs?

- Do you have problems tracking which of your products are under warranty and which have expired coverage for warranty?

- Are you, in short, unable to effectively perform your service management functions?

CANIAS ERP Service Management Solutions

CANIAS ERP provides the following functionality as part of its Service Management Solutions, which will be described in detail in this section:

- Incoming Call Acceptance and Customer Identification

- Product and Problem Identification

- Call Dispatching

- Call Monitoring

- Spare Parts Management

- Customer Satisfaction Monitoring and Service Centers Performance Monitoring

- Service Centers Accounting System

1) Incoming Call Acceptance and Customer Identification

When an existing or potential customer places a call to the company, customer information is retrieved during the call from the corresponding customer record maintained within the CRM (Customer Relationship Management) system. If the caller is a potential customer, a new record is created within the CRM system. The retrieved CRM records contain in detail all past contacts with the caller. Being able to access all pre-sales and post-sales information is important in providing better and faster service to the customer.

2) Product and Problem Identification

Our first task is to understand what the caller is requesting from us. If the caller is a customer, it means that he or she has a problem with a product purchased from our company. At this point, we need to determine information about the product the customer has purchased. We should keep in mind that the customer may have purchased multiple items from us, and it is imperative that we understand with which product he or she has a problem. Once the product has been identified, we can access the associated product record under the main CRM entry for that customer, and obtain all transactions that have taken place during and after the sale. These may include any details about product installation, other problem calls placed previously for the same product, as well as the warranty status for the product. Based on this information, your call center or service department will perform the necessary dispatching for the call.

First of all, the service information defined for the product is checked by the system.

Then the relationship between the customer placing the call and the product is checked.

When was the product sold to the customer, is it still under warranty, what service calls were made in the past, if any, for the same product?

3) Call Dispatching

The personnel who is first in contact with the customer may have several options to dispatch the call.

The personnel who is first in contact with the customer may have several options to dispatch the call.

(Integration with the mobile devices that exist within the system is most crucial in this application. Thanks to integration with such devices as cell phones and PDAs, field personnel in remote locations can be automatically contacted and the response time to calls may be expedited. In return, the field personnel can quickly access detailed information about the customer through the use of these mobile devices.)

Capturing the service call into the system:

- Direct assistance over telephone: The call center personnel who has identified the problem is responsible for checking the FAQ (Frequently Asked Questions) lists and lists maintained for questions received previously over the telephone, to determine whether the same or a similar problem has been previously observed. If the problem has indeed been encountered before, the solution should be described to the customer over the same call. During this process, integration with CANIAS ERP's Document Management module is used. As a result, the call can be closed immediately.

- Forwarding of call to internal service department: Based on the type of problem and the situation faced by the customer, this option should be used if the call is to be handled by the internal service department of your company. Usually, this option is used in cases where information about the product is available through the customer data record, when a problem report has already been established as a result of a previously placed call and the problem has not yet been resolved, and when your organization does not have solutions partners authorized for service.

- Forwarding of call to third-party authorized service partner: If your company makes use of authorized service partners in various locations, the servicing of the problem can be forwarded to the service center at the appropriate location based on the information gathered up to this point from the customer. As CANIAS ERP systems can be accessed over the web, your authorized service partners will be entering service transactions directly into your corporate database, and you will be able to monitor all service data in real-time.

4) Call Monitoring

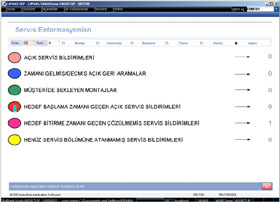

You are able to monitor all service bulletins entered into the system. In this manner you can access all your service records through a summary screen and then drill down for details as necessary.

5) Spare Parts Management

Spare parts used for servicing of products is monitored in the system through Product Tree, Route Information and Inventory Management modules. The data associated with spare parts and labor flow automatically into related modules within the system. In this manner, the invoices for service are automatically transferred into accounting, and inventory management is attained. Additionally, critical inventory levels of parts used in servicing can be defined within materials management, enabling automatic planning for future needs.

Spare parts used for servicing of products is monitored in the system through Product Tree, Route Information and Inventory Management modules. The data associated with spare parts and labor flow automatically into related modules within the system. In this manner, the invoices for service are automatically transferred into accounting, and inventory management is attained. Additionally, critical inventory levels of parts used in servicing can be defined within materials management, enabling automatic planning for future needs.

Furthermore, you will be able to track in real-time the spare parts inventories maintained by your authorized service locations, as service transactions at those service centers will be taking place online.

6) Customer Satisfaction Monitoring and Service Centers Performance Monitoring

Customer satisfaction is tracked using customer surveys defined for each type of service. Post-service performance results of service centers can be monitored thanks to the integration of the service module and the CRM module.

Additionally, the customer surveys can also be used as checklists to help you assure that a service call has been completed in full.

7) Service Centers Accounting System

Thanks to the overall integration provided by the system, all invoices issued to the customer or to authorized service centers, and all payments issued within the service module are automatically transferred to accounting and monitored.

The service department within your organization automatically obtains the service information from the system for the service to be invoiced, and creates the corresponding invoice. The spare parts and labor that has been declared to that point in time are priced on the invoice.

The invoices created within the system by your service department are checked by your personnel who have approval authority, and following the approval, related invoices become printable.

| |

|

- - Technical service call management:

- Management of technical service calls internal to the organization

- Management of technical service calls related to the solution partners

- Service requests from customers

- Service forms

- Periodic services

- Periodic maintenance planning

- Periodic control planning

- Post-installation activities

- Tracking of product serial numbers

- Product location information

- Product purchase, sale and installation information

- Monitoring of warranties

- Inventory transaction history

- History of services performed for the product

- Transaction types:

- Assembly

- Disassembly

- Revisions

- Repairs

- Service

- Multiple product monitoring

- Detailed customer information

- Targeted start and end durations

- Checklists

- Costs

- Invoice information

- Associated service bulletins

- Opportunity for approval of newly created plans prior to forwarding to manufacturing and purchasing departments

- Flexible and detailed reporting

|

|

| |

|

As is the case with all other CANIAS ERP modules, the Service module is structured so that it is fully integrated with other modules. The features associated with this integration can be summarized as follows:

- The detailed records associated with the customer initiating the service request is monitored through the Main module and the CRM (Customer Relationship Management) module.

- Spare parts and service materials are defined through product trees.

- Service operations are defined through routes.

- Spare parts and service materials requirements are detected by the MRP module and planned to be supplied. Information flows to the purchasing module and the related purchasing transactions are monitored. The tracking within the system of the purchased spare parts is performed in an integrated manner through the inventory module.

- Service center capacity for which planning has been accomplished is optimized through the use of the Capacity Planning module.

- Service costs are calculated through the Actual Costs module and the organization is enabled to obtain a clear view of the costs associated with servicing and warranties.

- Chronic complications detected at service units can be reflected to the production routes and quality control criteria. In this manner, information about the product obtained from the post-sales unit can be used to improve production.

- Issuing of all service invoices and payments are carried out in a manner that is integrated with the Accounting (Finance) module.

|

|

|

|