CANIAS MRP - Material Requirements Planning

Increase Your Competitive Strength with CANIAS ERP Material Requirements Planning (MRP)

It is vital for a production company to plan its material procurement and production accurately and in due time so its

activities may be conducted in a healthy manner. The aim to meet requirements on time in variable and challenging

market conditions brings in its wake questions and problems that must be solved.

- How must I plan the procurement in accordance with current demand?

- When must I produce or purchase what and in which quantity?

- How can I prevent the formation of stock surplus to requirements as I try to meet demand?

- How can I reduce the number of unfinished tasks due to insufficient materials?

For questions such as these, the Material Requirements Planning (MRP) Module of our CANIAS ERP solution will be your most efficient assistant.

Keep Your Resources Under Control

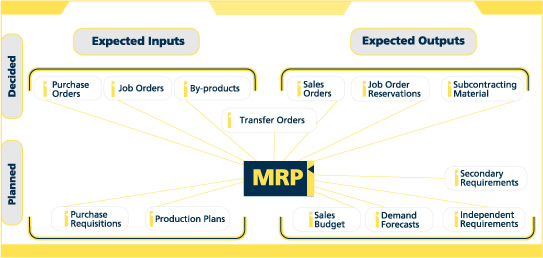

To put it simply, the CANIAS ERP Material Requirements Planning (MRP) Module helps you establish the purchase and procurement balance of your company. The module works with the Product Design, Budget, Inventory, Sales, Purchase and Production Management Modules in a fully integrated manner. This helps you identify the location of products and items required for your products on the time axis and easily plan production resources.

Using this module, taking material records, product tree and route information in the CANIAS ERP as a basis, you can automatically produce requirement-fulfilling system suggestions such as purchase requests, production plans and transfer orders considering requirement components such as sales orders, sales budget, demand forecasts and independent requirements.

Reduce Your Inventory Costs

The most noticeable reward of the module will be reduced inventory. You will get rid of unnecessary inventory increase, since it will become easier to supply stock sufficiently and on time. The module always considers the minimum delivery time and the most suitable purchase quantity in accordance with cost to present you production and purchase suggestions.

Provide Intradepartmental Coordination

It becomes possible for the sales, purchase, warehouse and production departments of your company to work a lot more efficiently and with a higher degree of coordination after the CANIAS ERP Material Requirements Planning (MRP) Module is put into service. The staff and directors at the relevant departments may obtain up-to-date and reliable data directly from the CANIAS ERP system. Therefore intradepartmental clashes due to late, incomplete or inaccurate information will disappear.

Increase Your Productivity

The production activity of your company may be planned in a more efficient manner with the CANIAS ERP Material Requirements Planning (MRP) Module. With the purchase requisitions and production plans produced by the module, it will be much easier for you to ensure that the required material is at the right place on time. Sound planning reveals its impact in diminished delivery time and in the increase of your productivity.

Increase Your Competitive Strength

Effective planning and increased productivity increases the trust of other departments in your production planning department. The most important benefit of this reveals itself in a slightly more indirect manner on the sales and marketing departments. The increased trust in the force behind these departments that are in direct dialogue with the customer, namely the production department, will then be echoed in a short time in the offers and orders you make. As a result of this, your competitive strength will increase.

| |

|

- Planning according to various batch size methods

- By requirement,

- By maximum level,

- By fixed amount

- By economic batch size

- By procurement period leveling amount

- Planning by reorder stock level

- Planning by demand expected to form in future periods using the deterministic method

- Net Change Planning

- Single material planning

- Customer-specific planning

- Planning by Daily, Weekly and Monthly periods.

- Keeping non-MRP stock with special stock type management

- Planning of subcontracting, produced material as well as the materials transferred from other installations

- Graphic representation of some results on material basis

- Requirement Orientation (use of alternative materials)

- Planning with Sales Orders, Sales Forecasts and Sales Budget data

- Modification in automatic production planning and manual plan input facility

- Backward planning from delivery date

- Forward planning from today

- Time parameters

- Pre-production Security time

- Post-production Security time

- Plan interval

- Flexible reporting on results

- Order status report

- MRP results display from other relevant modules

- The transformation of purchase requisitions and production plans to purchase orders and production orders

- Identification of main data deficiencies before planning with MRP messages

- Approval option before the communication of the formed plans to production and purchase departments.

|

|

|